Did you know South Korea is silently engineering the most advanced industrial revolution the world has ever seen? At the core of this overhaul lies the smart factory—a concept promising to redefine manufacturing on both a digital and human level.

This change isn't just another tech upgrade; it's a seismic shift expected to reshape global supply chains. As tensions in traditional industrial powerhouses rise, Korea's leap towards Industry 4.0 stands to alter economies, industries, and potentially, our future.

South Korea's quiet rise through smart factory expansion might sound like a distant narrative, but it's one filled with surprises. Surprisingly, this relatively small nation is now leading the world in smart technology adoption rates, surpassing even its American and European counterparts by significant margins. The implications of such a rapid technological embrace are far-reaching, not only altering industrial practices but also setting a global precedent for what digital factories can accomplish. But that's not even the wildest part...

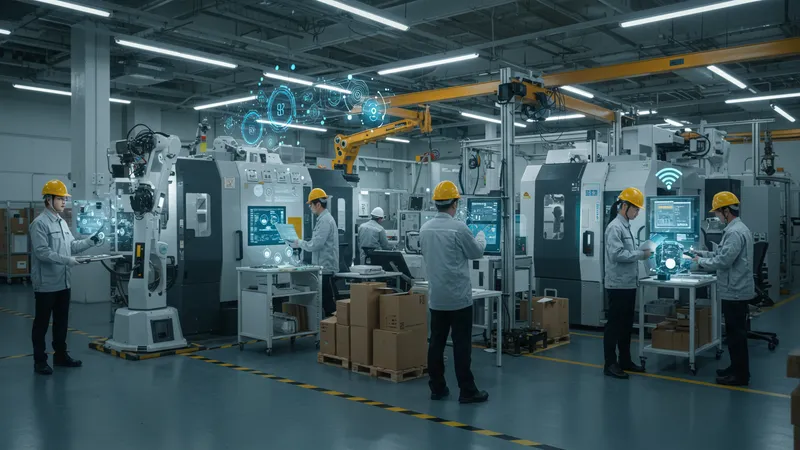

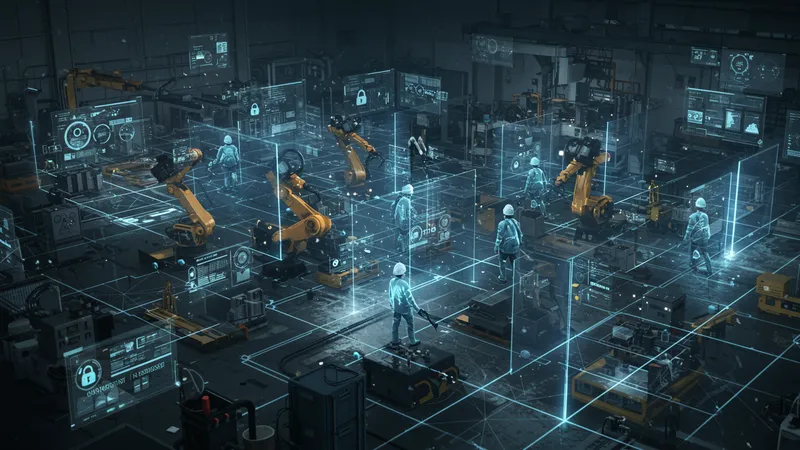

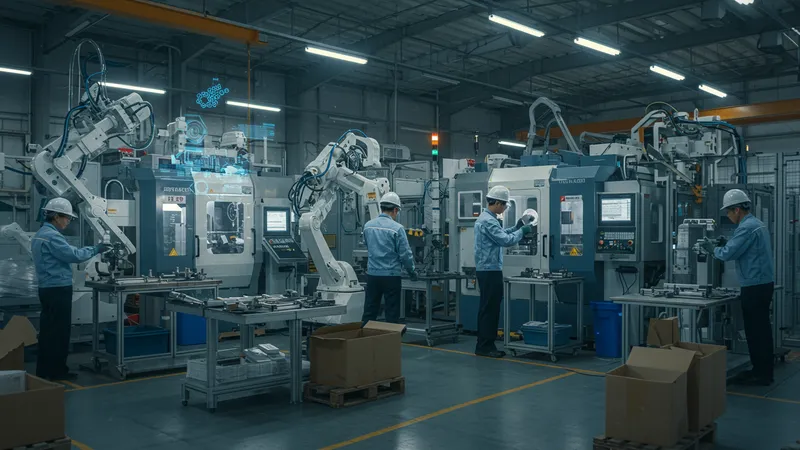

You've heard of robots replacing human labor, but in South Korea’s factories, AI-driven machines are being developed to collaborate alongside humans, enhancing productivity and not merely substituting it. This coexistence is spawning new roles and requires a novel skill set for human workers, defining an entirely new class of expertise. This pivot challenges the existing notion of technology just as a replacement tool. But what unfolds next could redefine industrial labor partnerships entirely...

This is just the beginning of a story that keeps getting more intriguing. We’re about to uncover how South Korea leveraged technology to transform from a tech follower to a global leader. What happens next shocked even the experts...

The transformation didn’t happen overnight. In fact, South Korea’s transition from traditional manufacturing to smart factories was a decade-long voyage woven with strategic priorities. Unlike many countries, the focus was on creating synergy between technology and human capital from the outset. Investing heavily in education and training, South Korea ensured its labor force not only adapted but thrived amidst evolving industrial landscapes. But there’s one more twist—this shift was deceptively seamless and outrageously fast.

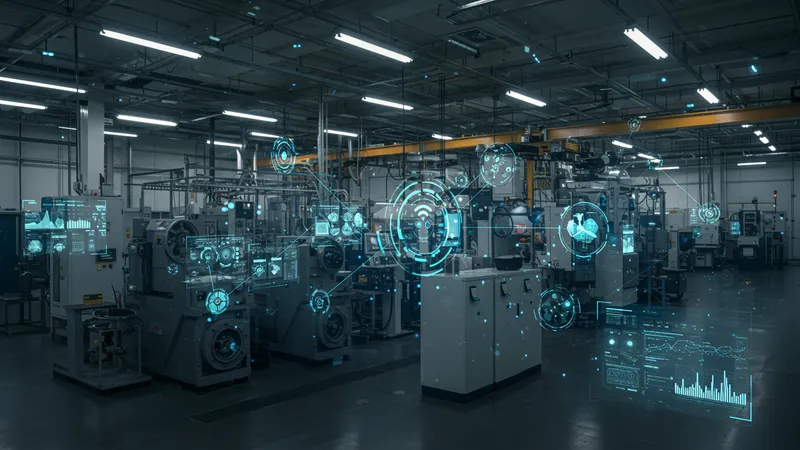

One compelling detail often overlooked is how South Korea's hybrid approach blends advanced technology with human intelligence, creating factories capable of self-diagnosing and correcting errors. This isn’t a mere enhancement; it’s a revolutionary leap ensuring minimal downtime and optimal output. The collaboration between IIoT devices and human insight in identifying bottlenecks is stunningly efficient, something even Silicon Valley is looking to emulate. What you read next might change how you see this forever.

As we dig deeper, the sheer scale of smart city initiatives integrating with these factories becomes apparent. South Korea is not just focusing on the factories themselves but creating an ecosystem where data flow is seamless from urban sensors to production lines, significantly optimizing the supply chain. It’s as if each component communicates in a synchrony reminiscent of a futuristic assembly line from a sci-fi movie. But there’s another angle that’s even more promising...

Intriguingly, South Korea's rise as a smart manufacturing powerhouse is complemented by government policies that incentivize innovation and infrastructure development. It's a well-crafted strategy that ties industrial growth to national prosperity, avoiding the pitfalls of modern industrialization like inequality and environmental neglect. Stay with us as we unfold how this approach is technologically comprehensive and socially deliberate at heart.

The role of the Internet of Things (IoT) in South Korea's smart factories cannot be overstated. IoT technology is not only revolutionizing efficiency in these factories but entirely reshaping how production processes are monitored and managed. Utilizing sensors, devices, and analytics, the IoT setup allows for real-time updates on machinery health, predictive maintenance schedules, and energy usage optimization. This connectivity ensures factories operate with unparalleled precision and minimal waste. But the story doesn't end there...

Behind the successful deployment of IoT is a robust digital infrastructure that supports high-speed communication and data transfer. South Korea’s commitment to cutting-edge internet capabilities enables instantaneous data exchange, creating a near-invisible web of coordination across factory floors. This infrastructure acts like a nervous system, facilitating operational agility unheard of in most parts of the world. However, it’s South Korea’s ingenious application of this infrastructure that really sets it apart.

The integration of IoT in these settings also initiates a dialogue between intelligent machines and human operators, optimizing bread-and-butter activities like inventory management and quality checks. Perhaps most fascinating is the adaptation of IoT for more intuitive human-machine interactions which, not only improve productivity but also enhance worker satisfaction by reducing mundane tasks. The ramifications stretched beyond manufacturing, offering insights into enhancing human life itself, a promise IoT seems unprecedentedly close to fulfilling.

Yet, the scalability of IoT solutions in South Korea doesn’t occur in isolation. It hinges on network capacity and regulatory environments that support experimental applications and technological progression. As the nation expands its smart grid to accommodate burgeoning IoT infrastructure, the gap widens between it and other countries struggling with legacy technologies. We’re about to explore how this IoT-fueled quest translates into economic dividends and unforeseen societal shifts.

South Korea’s formidable investment drive in smart factories and IIoT reflects not just a hunger for technological advancement but a profound economic strategy. The investment figures themselves are staggering, with billions being poured into R&D, infrastructure, and specific technology ecosystems. These investments are transforming local economies and reshaping global markets. Still, the true financial narrative only begins to reveal itself when looking at the multiplier effects...

By positioning itself as a tech innovator, South Korea is inadvertently sowing the seeds for a booming startup ecosystem. The demand for smart factory-related services stimulates entrepreneurship and creates niche markets burgeoning with opportunities. The vibrancy of this ecosystem is most apparent in the proliferation of high-tech startups catering to diverse facets of the industrial revolution. It’s not just a tech transition—it almost resembles a socio-economic reimagining that interlinks established corporations with nimble innovators.

An intriguing aspect often underestimated is how this investment in smart technology is having a ripple effect on employment rates. Contrary to the narrative of machines replacing humans, South Korean factories are generating new job categories, necessitating advanced skills and ongoing education. This investment in human capital works hand-in-hand with technology, dissolving stark lines between manual and tech-savvy professions. This novel workforce integration is now becoming a model for others aiming to emulate this industrial harmony.

The benefits of South Korea’s industrial foresight extend beyond its borders, enhancing its fiscal standing and cultural influence on a global stage. As foreign investors pour into South Korea, seeking strategic partnerships and innovation exchange, the nation enjoys a revitalized image as both a manufacturing and cultural powerhouse. But what’s next as Korea capitalizes on its momentum and fosters long-term, sustainable economic growth? Stay tuned to capture the full spectrum of this phenomenon.

In a world grappling with environmental concerns, South Korea’s embrace of smart technology is a beacon for sustainable industrial practices. Leveraging smart factories, energy-efficient processes, and IoT, South Korea is directly addressing climate change challenges through innovative solutions that significantly reduce carbon footprints. This green transformation isn't merely about compliance; it's an integrated approach weaving sustainability into the very fabric of production. But there’s so much more beneath this transformation layer...

Harnessing renewable energy sources and implementing cutting-edge emission control technology, South Korea’s smart factories are becoming self-regulating ecosystems. These sustainable initiatives reduce waste, optimize resource usage, and promote energy efficiency, aligning industry operations with environmental stewardship. In this eco-centric vision, technological advancement is seamlessly interlaced with ecological responsibility—a paradigm shaping the future of global manufacturing norms.

Significantly, it’s the synergy between local governments, industry leaders, and the tech community that propels these green initiatives forward. By fostering a collaborative environment, these entities ensure that sustainable practices are implemented at every level of the production chain. The governmental backing further validates these efforts, creating incentive structures that reward eco-friendly practices and innovations, essentially setting a benchmark for environmentally-conscious behavior amongst industries worldwide.

However, the journey towards sustainability is only just beginning. South Korea's continual experimentation and innovation promise even greener technology on the horizon. The insights gained and technologies developed here might well serve as the global playbook for a sustainable future in manufacturing—a testament to how technology can coexist with nature in harmony. Explore how these insights might help other global players chart their sustainable paths forward.

The rise of smart factories in South Korea is prompting a re-evaluation of the human-machine dynamic, redefining roles traditionally held by humans and machines. Unlike other industrial transformations, this is a narrative of collaboration rather than replacement. Here, machines equipped with AI and IoT enhancements serve not to eliminate human intervention but to augment human capabilities, fostering teamwork that elevates productivity and creativity. But there’s a fresh perspective that this evolution brings forth...

The integral role humans play in these smart factories is underscored by a strong emphasis on education and re-skilling. South Korean workers are encouraged to adapt to new roles within an ever-evolving technological framework. Training programs aimed at closing the skill gap between technology and the workforce are essential, ensuring that workers not only understand new technologies but also leverage them to enhance operation quality and efficiency. This people-first approach is as critical to the revolution as the technology itself.

One of the fascinating developments is the clear partition of labor where human ingenuity is harnessed for complex problem-solving and strategic tasks, and machines handle precise, routine operations. This balance transforms the workplace dynamics, infusing a new level of cooperation between the two and allowing for innovation and efficiency to thrive. The resultant environment embraces a progressive work culture that, in some ways, rewrites conventional labor paradigms for the better.

As these interplays continue to evolve, South Korea is inadvertently crafting the blueprint for what future workplaces around the world might resemble. By championing a cooperative approach, whereby technology complements rather than competes with human effort, South Korea sets a precedent for holistic industrial harmony. The implications of this man's machine synchronicity could fundamentally shift workplace dynamics globally, offering a rejuvenated outlook for industries transitioning to Industry 4.0.

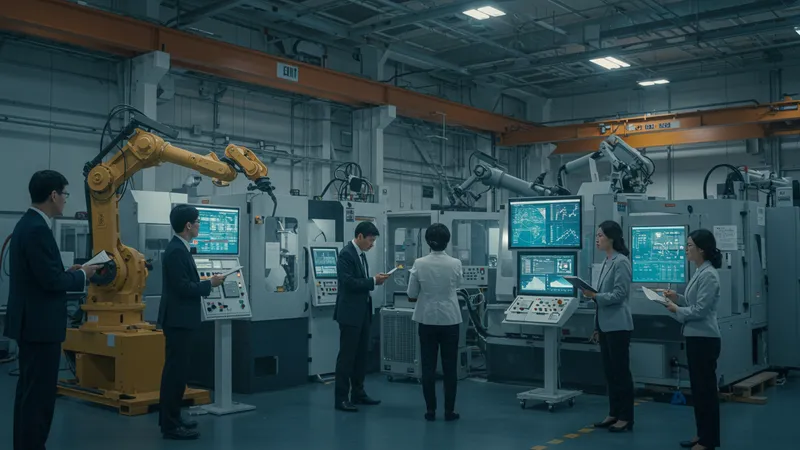

At the heart of South Korea's industrial transformation is a series of aggressive national policies that effectively accelerate the embrace of smart technologies. These policies act as the cornerstone for a thriving industrial ecosystem, tailored to foster innovation, bolster economic competitiveness, and mitigate environmental impacts. The strategic deployment of supportive policies is transforming South Korea from an industrial participant to a pioneering leader in smart factory initiatives. But the stakes and strategies involved go even deeper...

Government initiatives are steadily removing roadblocks to smart technology deployment. Fiscal policies that offer tax incentives encourage local companies to invest in cutting-edge technologies essential for smart manufacturing. They function not just as facilitators of technology adoption but as beacons, encouraging industries to lean into revolutionary changes with confidence. The fostering of such a tech-positive environment is crucial in keeping the momentum for industrial innovation alive.

Through fostering partnerships between government bodies and key industry players, South Korea is enhancing collaborative efforts that focus on establishing technology-driven industrial sectors. These collaborative frameworks enable collective engagement in research and development endeavors, generating a pool of knowledge critical for innovation. By leading with policy, South Korea is ensuring that real-time feedback loops link industrial practices with legislative support systems.

But, it’s not just about national success; it’s about international clout. By spearheading smart technology integration, South Korea is laying down a blueprint for international adaptation, using its position to negotiate more favorable terms in global technology exchanges. Policies crafted today shape the dialogues of tomorrow, where South Korea stands as a testament to what synchronized policy and technology advancement can achieve. The revelations about this influence on global policy pathways are just beginning—and what comes next might redefine international industrial strategies completely.

Beyond the economic and technological marvels lies a more profound transformation— the reshaping of South Korea's identity as an innovation hub. From world-leading music and entertainment exports to groundbreaking technology, South Korea’s industrial advancements are folding seamlessly into its cultural identity. This is not merely a story of industry evolution but a cultural metamorphosis that vibrates across the global stage. Yet, the dimensions of this cultural tide are as layered as they are fascinating...

Historically seen as economic followers experiencing rapid post-war industrialization, South Korea has emerged as a torchbearer for technological sophistication. This transition augments national pride and thrusts South Korea's cultural exporters, like K-pop and cinema, into the limelight, collectively elevating South Korea’s profile. The infusion of cultural innovation within technological advances creates an appealing and holistic national narrative—the kind of branding few nations achieve.

The cultural echo of smart technology is reflected in consumer products too, as seen with electronics giants embracing green energy in their mainstream offerings. The spirit of innovation is woven into everyday experiences, altering consumer perceptions globally. South Korean technology and culture not only generate soft power but also shape consumer expectations worldwide, raising the bar for other nations and industries to rise to.

And this cultural evolution is uninterruptedly fluid, adaptive, and holistic. By intertwining technology and culture, South Korea is creating a lifestyle brand unto itself—blurring the lines between entertainment and industrial might, producing a cohesiveness that very few countries rival. It's an identity in constant gestation, fueling a vibrant national narrative that will invariably inspire both Confucian and global modernity, reflecting the adaptability of culture through technologic progression.

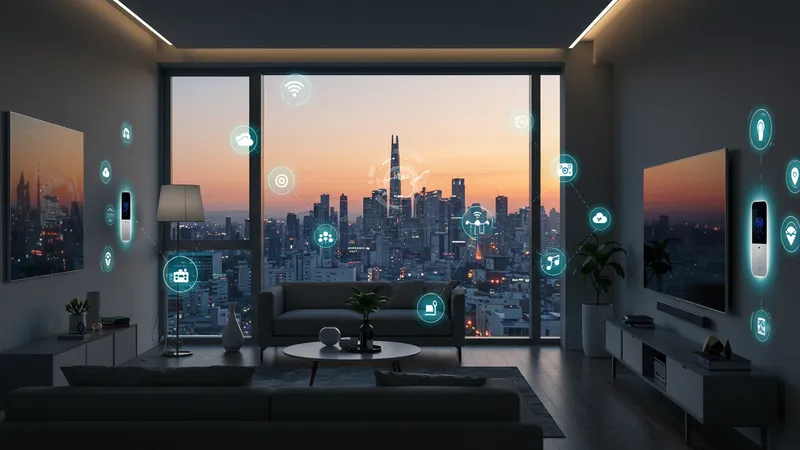

Smart factories aren't just revolutionizing industrial landscapes; they are also indirectly shaping our homes. South Korea's extensive industrial and technological progress is subtly fueling the global boom in consumer electronics, particularly in the evolution of the 'smart home'. As smart factories lead in innovation, their offspring manifest as sophisticated, interconnected home devices enjoyed worldwide. Here's where the intersection of manufacturing and daily life unfolds in unexpected form...

Fueled by ever-advancing IIoT technologies, South Korean firms are crafting home environments where connected devices seamlessly interact, making daily life more convenient, efficient, and sustainable. This progression is not just reshaping consumer expectations; it's altering the very essence of home living, embedding automation and intelligence at the core of domestic spaces. As with factories, these homes are tailored for optimization and ease, signaling a future where the boundary between living space and digital control blurs further.

But it’s the scalability and affordability of these products that truly signal a paradigm shift. As production becomes more efficient due to smart factory practices, high-quality smart home devices become accessible across diverse economic strata—breaking the notion that such sophistication is reserved solely for the financially privileged. This democratization of technology draws from a deeper industrial ethos rooted in inclusivity, geographic reach, and ultimately, transcending luxury branding.

As global demand for South Korean consumer electronics surges, the reflection on smart factory growth is evident. Consumers around the world find themselves at the helm of an innovative lifestyle movement rooted in South Korea’s industrial strategies. The shifting dynamics of modern living, propelled by this progression, offer a tangible glimpse into what is possible when industry propels everyday life, continuously bridging the gap where technology and humanity coexist idyllically. And as this unfolds, pondering the next natural progression in this smart ecosystem becomes even more captivating.

As South Korea sprints through the corridors of advanced industrial technology, it stands firm on the lessons learned and foundations laid by historic industrial experiences. It’s not by chance that South Korea effectively integrates new technologies as they emerge but borrowing wisdom from bygone eras adds incomparable value. The fingerprints of past innovation attempts, both successful and flawed, narrows current undertakings’ risks, furnishing today's forward-thrust with insightful caution...

In pioneering smart innovations, South Korea emphasizes failing forward—a culturally resonant strategy that recycles challenges faced into knowledge bases for future endeavors. This propensity to refine processes rather than ditch them empowers agile adaptivity, ensuring strategies remain tethered to real-world applications instead of distant, unattainable ideals. It’s this connection between historical insight and contemporary application that fuels the constantly rotating wheels of progress.

The amalgamation of old and new manifests in smart factories that function with remarkable proficiency, embracing a continuous improvement ethos linked back to historical industrial philosophies like Kaizen. South Korea systematically enforces scientific abstraction with practical deployment, defining a manufacturing methodology based on empirical learned applicability rather than trial and error alone. This conserves resources, time, and ensures scalability doesn’t occur at the expense of quality.

The enduring lesson here challenges industries to diversify their narrative to embrace experiential learning and historical depth, transitioning seamlessly from learning to mastering. As South Korea embarks on continuous innovation propelled not just by cutting-edge technologies but also by seasoned wisdom and learning, the resultant synergy of support and substance fortifies its manufacturing supremacy—a model of dynamic adaptability and resilience in the rapidly unfolding Industry 4.0 landscape.

The ripple effect of South Korea’s foray into smart factory innovation is generating waves globally. From technological adoption to policy crafting and the restructuring of educational paradigms, other countries are closely observing, adapting, and gleaning insights from South Korea’s advancements. This translates into a strategic interconnectivity that potentially alters global industrial powerhouses’ dynamics, threatening to eclipse traditional giants with newfound technological brilliance...

Companies around the world are keenly influenced by South Korea’s manufacturing transformation, which they see as a benchmark for modern industrial operations. These aspiring nations appreciate the blend of digital sophistication with traditional manufacturing ethos, guiding them in crafting their versions of an ideal industrial environment. This transference of knowledge subsequently aligns industrial growth strategies with global competitiveness, benefitting nations from the cross-pollination of ideas.

Education reform emerges as a recurring theme in global adaptation. By placing emphasis on developing tech competencies across the board from vocational schools to higher education platforms, countries recognize this skill-sharing as asymptotically linked to economic growth. Through this exchange of ability, nations find themselves inspired to radically reinvent not just their factories, but also their workforce, echoing South Korea’s commitment to perpetual learning and skills enhancement.

The resulting global change challenges existing power structures and defies conventional notions of industrial growth. The virtual democracy fostered by smart factory expansion traverses traditional economic lines, encouraging transparency, efficiency, and sustainability. Beyond tracing South Korea's shadow, these global shifts raise more profound questions about the future of industry and whose narrative will dominate in years to come when technological and cultural exchanges shape the global industrial landscape in new and unexpected ways.

South Korea’s deployment of smart factory technology transcends national boundaries not just physically through exports, but metaphorically, exerting substantial soft power across the globe. This microcosmic revolution is catalyzing interconnectedness and co-operation in ways neither anticipated nor documented before, highlighting industrial diplomacy as an undercurrent to international relations. But the subtleties embedded in this soft power narrative provide layers of intrigue...

The convergence of cultural influence and technological prowess ensures that South Korea wields an extraordinary level of soft power—encapsulated not just within tangible products but also in embedded technological values that proliferate universally. This unique brand of influence focuses not on cultural dominance but on a shared enhancement of technological standards, reflecting a collaborative form of power nurtured through mutual benefits rather than singular imposition.

The soft power wielded by South Korea seeps into global partnerships, invigorating digital trade relationships and fostering continual dialogue rooted in trust and reliability. Industrial partnerships undertaken on a shared footing reciprocate dividends far beyond profits, earmarking South Korea's technology not just as products but as essential collaborative foundations from which new possibilities burgeon indefinitely. These emergent relationships redefine connectivity, fostering alignments that value intent as much as they do productivity.

The emerging challenge is how nations weave this imported technological acumen into their fabric without losing inherent identity or autonomy. Navigating this complex tapestry challenges them to adapt in a way that reinforces local culture while benefiting from collaborative global interactions. Embracing technologies enriched with South Korean values encourages innovation while respecting sovereignty, potentially propelling an era where soft power aligns with concrete development, yielding world-improving possibilities stemming from collaborative beginnings.

With the rise of hyperconnected systems comes an accompanying challenge that's casting shadows on the incredible progress of South Korea's smart manufacturing: cybersecurity. As factories become digital ecosystems, the vulnerability to cyberattacks and data breaches escalates. The industry's push toward connectivity inadvertently exposes weak points that malicious attacks can exploit, threatening the incredible technological advances with potential setbacks...

Today, South Korean factories are stepping beyond traditional security measures to adopt cutting-edge cybersecurity solutions designed to preempt and respond to threats. By integrating physical and cyber defenses, they construct a fortified framework that enhances system resiliency against pervasive threats. While digital fortresses are erected, the dialogue surrounding privacy, data integrity, and legislative oversight urgently evolves, revealing an industry wary of triumph over foundational security.

Engagement with global cybersecurity entities underscores South Korea's commitment to guarding its burgeoning innovations. Partnerships with international tech-security firms ensure South Korea is not isolated in its defense strategies, promoting a unified global approach to safeguarding industrial sovereignty. These collaborations are increasingly vital, making cybersecurity less about isolated vigil and more about shared responsibility amid an interconnected industrial world.

The presence of emerging threats challenges South Korea to trailblaze not just technologically but in creating ethical defenses where transparency and accountability rule. As industries address these concerns, the narrative flips from potential vulnerability to innovation-driven control, where futures are secured by adaptive technology rather than risked by inadequacies. Funky changes ripple effectively through policy, legislation, and daily operational practice, ensuring protection paves the way for unobstructed brilliance in the era of technological modernization.

In the heart of technological change lies a more human narrative—the social implications of smart factories that broaden the scope of what constitutes industrial value. Beyond economic gain, South Korea's industrial innovations redefine societal values by aligning technological processes with improved quality of life encompassing environmental stewardship, human development, and cultural resonance. Yet, as this redefinition unfolds, gathering societal shifts become evident...

The ripple effect extends to community development, where employment patterns are reshaped, offering career paths in realms emerging out of technological necessity. As workers transition into high-skilled roles, South Korea nurtures a populace endorsing continuous innovation—a society where human intelligence complements automation to create stable ecosystems of progress. The workforce thrusts forward, merging tradition with innovation, exhibiting how technology can raise societal standards and encourage collective betterment.

Furthermore, the mergers between industry and societal betterment craft pathways to sustainable living. South Korea's sophisticated technologies bring environmental rejuvenation, embracing eco-conscious production that minimizes waste while optimizing resources. This approach not only builds resilient communities but safeguards them against the specter of industrial excesses, creating a future where harmony between industry and the planet becomes the new norm rather than the exception.

However, redefining societal values through smart technology raises questions about access, opportunity, and innovation equity. South Korea’s ongoing task is to ensure these advancements translate across demographics, creating an inclusive industry revolution that echoes peace rather than exacerbates stratification. This unfolding narrative teaches that in embracing technological maturity, there lies an obligation to step beyond pure industrial prosperity to foster equitable, progressive, and harmonious human growth—thus harnessing technology as a servant of poise rather than a master of future intent.

The narrative that automation leads directly to job redundancy is no longer holding ground, especially within South Korea’s smart factories where robotics and people work in synergy. Instead of eradicating jobs, these establishments cultivate a cooperative fabric that bridges traditional employment with technological convenience. This workforce synergy, however, introduces unanticipated challenges poised to redefine work-life paradigms...

Central to defying the automation redundancy myth is a commitment to ongoing worker education and re-skilling strategies that empower employees. South Korean industries prioritize learning cultures that enhance workforce adaptability, ensuring workers can transition into roles that transcend technological integration. This blueprint for perpetual upskilling cements an environment where human roles are more aspirational than they were a decade ago.

Moreover, this cooperative model catalyzes the evolution of job roles within smart factories. Routine, monotonous tasks are seamlessly adopted by AI-driven machines, freeing human workers to focus on strategic, creative, and analytical endeavors. This shift fosters a resurgence in human-centric roles redefining the workplace into a space rich in collaboration, creativity, and intellectual pursuit—reversing detrimental automation narratives into stories of elevated human potential.

Yet, as this evolution unfolds, contemporary debates around work-life balance intensify. While smart roles offer intellectual stimulation, they demand high adaptability, sometimes challenging traditional constructs of working hours and personal time. Nevertheless, the essence of these shifts evokes a future where innovation and lifestyle harmoniously coalesce, echoing a symphony of progress resonating across technological advancements and human-centric employments—the paradigms of modern industrialism challenge both past perceptions and future ambitions.

In the grand symphony of innovation, South Korea harmonizes tradition with avant-garde technology, sculpting not merely factories of the future but entire ecosystems of industrial and societal evolution. The world observes, gathers insight, questions, and adapts as South Korea's revolutionary journey continues to unfold—one where technology serves humanity, and together they create a revolutionary narrative.Share this fascinating exploration into Industry 4.0's epicenter, and be part of the dialogue propelling this dynamic nation forward. Bookmark and return to discover even more revelations as we continue to unearth transformative journeys redefining global industry narratives.