You won’t believe the manufacturing potential lurking in the UK right now. Opportunities are bursting at the seams, but hardly anyone sees them coming.

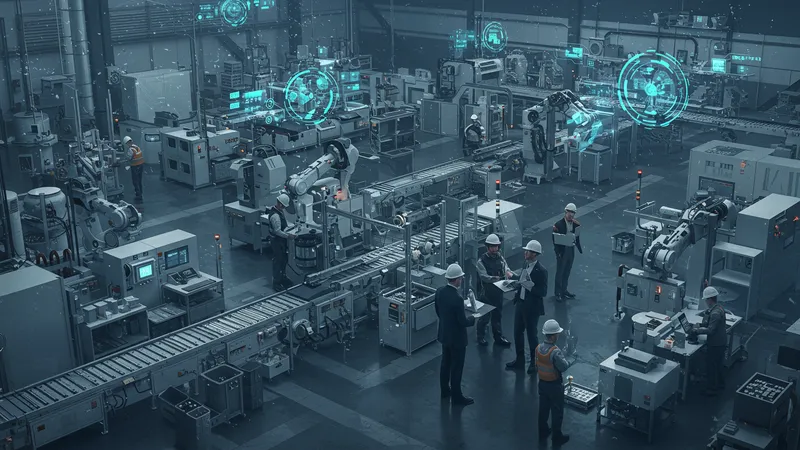

As global trends shift and industries pivot post-pandemic, the UK's manufacturing sector is set to transform dramatically. The demand for new talent has never been greater.

Did you know that the UK manufacturing growth rate has outpaced other sectors, even amidst economic downturns? It's not just about heavy machinery anymore; manufacturing now encompasses cutting-edge technology, robotics, and sustainability practices. This is where the future is being forged, quite literally. But that’s not even the wildest part…

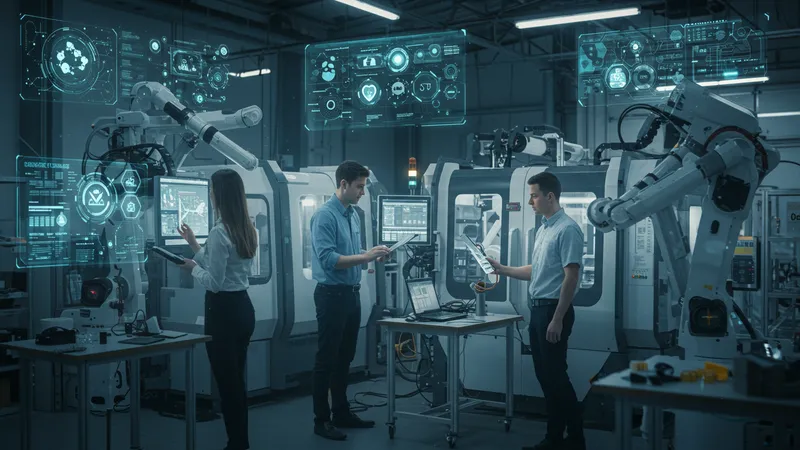

Careers in UK manufacturing are evolving at lightning speed. After all, who expected data analysts and software developers to be the backbone of this industry? The blend of technology and manufacturing is creating roles that never existed before. Yet, the true scope of these opportunities remains hidden from many. What happens next shocked even the experts…

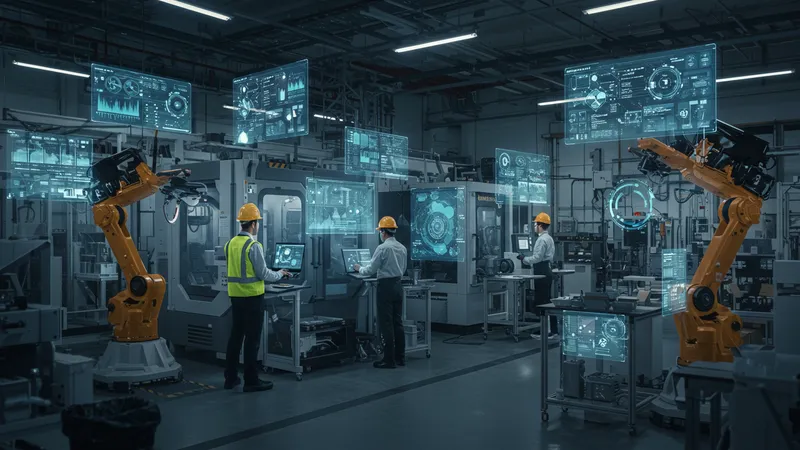

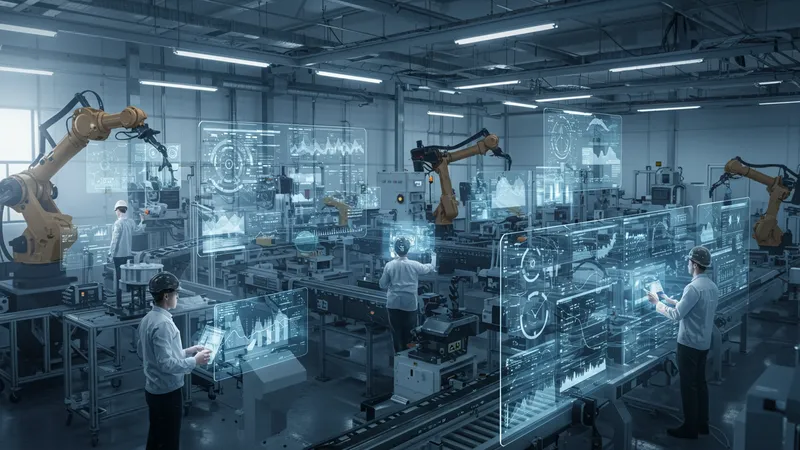

Imagine a factory where robots and humans work side by side, each complementing the other's abilities. This isn't science fiction. It's the reality of smart factories popping up across the UK, backed by AI and IoT. These advancements push productivity to unprecedented levels, while slashing costs and errors. But there’s one more twist…

Surprisingly, one of the greatest challenges isn't the technology – it’s finding skilled workers to harness it. The industry urgently needs tech-savvy professionals who can manage advanced systems and streamline processes. This shift is opening doors for a new breed of engineers and tech experts. What you read next might change how you see this forever.

Statistics show a staggering need for 186,000 skilled recruits each year until 2024. Yet, there's a knowledge gap. Many potential candidates overlook this sector because they envision it as something out of the industrial revolution. What if part of the solution involved rebranding the industry's image itself?

The push for greener technologies also plays a pivotal role. With the UK government's carbon targets waving like a flag of urgency, manufacturing is poised to innovate in sustainability. The sector is a leader in clean energy advancements and reducing carbon footprints. There's more to explore…

Unbeknownst to many, the UK manufacturing sector is rich with burgeoning career opportunities. From digitalization roles to robotics specialists, the sector offers an unexpected diversity. Underneath the guise of traditional expectations lies an ecosystem ripe for modern innovations.

Young professionals are starting to realize that these roles not only change how we produce but impact global sustainability efforts. For the first time, career growth and ethical responsibility align seamlessly. But this is only scratching the surface…

Businesses are investing heavily in training programs, offering unprecedented pathways for skills development. A STEM background can open multiple doors, each promising career trajectory. But what about those from non-technical backgrounds? The industry has room for them too! From compliance roles to logistics, the career path options can be surprisingly broad.

Outside perceptions often focus on the past glories of British manufacturing. Yet, a quiet, transformative revolution is happening, representing a dynamic, flexible future. This could be the perfect moment to explore such overlooked opportunities.

In a world craving fresh talent, apprenticeship schemes across the UK have become something of a secret weapon for the manufacturing industry. Unlike traditional education, apprenticeships provide hands-on experience directly within the industry. It's a fast track to mastering new skills while earning.

Companies like Rolls-Royce and BAE Systems have led the charge, investing significantly in their apprenticeship programs. But here’s the kicker: these aren’t just for school leavers. Adults seeking career changes can also hop on board. But there’s a caveat…

Nationwide, the number of available positions far exceeds the number of applicants. Misunderstandings about what modern apprenticeships offer often deter potential candidates. Could a wider awareness campaign spark a trend shift across apprenticeships in 2024?

Countless stories exist of apprentices swiftly climbing the ranks, achieving qualifications that rival university counterparts. It's a unique route offering both practical and academic advancement, redefining career success in the process.

Historically male-dominated, the manufacturing industry in the UK is witnessing a paradigm shift with more women entering its ranks each year. Yet, misconceptions persist about the roles women can play here.

Initiatives like the “Women in STEM” campaign are instrumental in diversifying the workforce. These programs draw attention to endless opportunities and challenge traditional gender roles. But there are hurdles yet to leap…

Encouragingly, the gender pay gap within UK manufacturing has been steadily narrowing. Women are now also stepping into high-level positions, influencing key decisions in tech implementation and sustainability initiatives.

This paradigm shift hints at a revolution that could make the sector more inclusive while unlocking untapped potential. Are we on the cusp of a gender revolution in British manufacturing?

The race towards a carbon-neutral future has altered manufacturing processes fundamentally in the UK. Sustainability isn’t just a buzzword; it’s now a non-negotiable entity shaping practices from production to packaging.

From adopting renewable energy sources to innovating eco-friendly materials, the industry's sustainability measures are setting new global standards. But skeptics question if these changes are mere window-dressing…

In fact, report after report confirms that sustainable practices correlate with increased efficiency and cost savings. These initiatives are not only environmentally conscious; they're economically beneficial.

The ripple effects transform market competitiveness, with early adopters gaining significant lead over their peers. How far can these trends propel us towards a greener future, and at what speed?

The skills gap is an ever-growing concern within UK manufacturing. As technological advances outpace educational adaptations, the challenge lies in equipping the workforce adequately.

Programs focused on STEM education are essential for bridging this gap. Government incentives and industry partnerships support these initiatives, creating a smarter, more adaptable workforce. But can these programs scale fast enough?

Technology integration, while beneficial, exacerbates the existing gap by requiring employees to take on increasingly complex roles. Upskilling and reskilling are crucial. Could an overhaul in curriculum design make a tangible difference?

Not only does addressing the skills gap ensure sustained growth, but it catalyzes innovation. The onus is on academia, industry leaders, and policymakers to jointly drive this forward-thinking agenda.

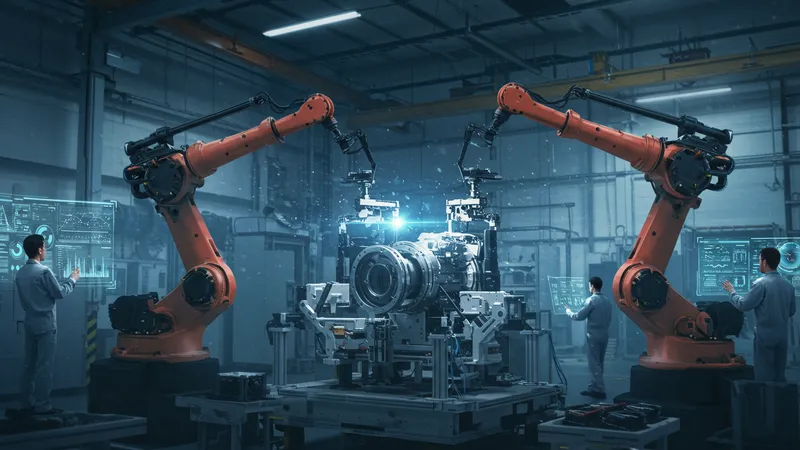

Automation and robotics are redefining the human workforce within the manufacturing sector. Robots are now handling tasks once considered too dangerous, complex, or tedious for humans.

Far from replacing humans, robotics enhances human capabilities, allowing focus on strategic innovation and creative problem-solving. But what does this mean for traditional roles?

Increased robotics usage calls for specialized skills, introducing new job categories in maintenance, programming, and design. With such rapid tech adoption, what will the future workforce look like?

The balancing act between robots augmenting human abilities and them overtaking labor jobs is delicate. Navigating this transition is key to future-proofing industry roles and ensuring economic stability.

In a world where efficiency reigns supreme, supply chain innovations are helping UK manufacturers stay ahead. Digital tracking systems, blockchain, and real-time data analytics have revolutionized how businesses handle logistics.

Increased transparency and traceability are transforming supply chains from reactive systems to predictive networks. But are these just fancy words for age-old practices?

These innovations allow companies to anticipate and mitigate disruptions, offering a competitive edge. However, reliance on technology presents its own set of challenges. What happens if these systems fail?

Constant innovation and adaptability are the new cornerstones of supply chain management, ensuring resilience against unforeseen challenges. The implications for small and large manufacturers alike could be profound.

The UK government plays a crucial role in fostering growth within the manufacturing sector. Through policy changes, funding, and strategic partnerships, their influence is both direct and indirect.

Initiatives like the Industrial Strategy Challenge Fund drive investment into cutting-edge sectors, ensuring manufacturing remains a global leader. But are these interventions enough to spark needed growth?

Funding support cushions industries venturing into uncharted territories, particularly in technology adoption and innovation. These resources fuel growth, leading to substantial economic returns.

The government's approach intertwines with broader goals of education reform and sustainable practice advocacy. With continuous reassessment, its impact remains a point of reflection and discussion for stakeholders.

Brexit has been a pivotal moment for UK manufacturing, creating both challenges and opportunities. Tariffs and border delays have forced companies to rethink strategies and optimize supply chains.

Despite initial setbacks, some have heralded Brexit as a chance to innovate and reshape trade relationships on favorable terms. But has reality matched the rhetoric?

Manufacturers remain cautiously optimistic, yet strategic shifts are challenging long-established norms. They look to diversify networks, tackle rising costs, and navigate a complex regulatory landscape.

While the definitive wake of Brexit remains partially shrouded, the sector's adaptability will be a legacy of the post-Brexit era — rewriting British manufacturing’s narrative.

Digital factories have emerged as game-changers, offering agile production capabilities and massive customization potential. They represent digitally enhanced operations designed for the future.

Fusing software with traditional manufacturing, they’ve unlocked pathways for real-time adaptation and minimal downtime. How can they further revolutionize processes already thought efficient?

Pioneers showcase the immense potential by combining machine learning, big data, and cloud computing, driving these advancements towards industry norms. Can other countries keep pace?

While entirely digital factories might seem ambitious, their incremental implementation proves effective, suggesting an intriguing blueprint for the industry's evolution.

Often seen as the future of complex manufacturing, additive techniques like 3D printing are reshaping production. They enable unprecedented design freedom and resource efficiency.

Customizable, lighter, and more robust products emerge, challenging traditional production methods. Could this technique signal the decline of conventional manufacturing processes?

Recent breakthroughs in materials and speed of production make large-scale adoption viable. However, integrating additive manufacturing into existing workflows poses hurdles.

The promise it holds with rapid prototyping transitions to a broader market application, underscoring implications for innovation and cost-efficiency amidst rapid technological advancements.

With export horizons expanding, UK manufacturing's global footprint is more pronounced than ever. Companies leverage international markets, reshaping supply chains to seize new opportunities.

Worldwide demand for quality British goods persists, with sectors like automotive and pharmaceuticals taking center stage. Could there be untapped avenues in emerging markets?

Navigating tariffs and regulations highlights adaptability in this landscape, prompting strategic alliances and investment in local bases. How might international collaboration evolve this dynamic?

The global footprint extends beyond exports, marking the sector as a critical player in international technology and innovation corridors vital to the UK economy’s overarching growth.

The productivity gap is a notorious impediment to UK manufacturing’s full potential, where output lags despite talent and technical progress. Identifying and enacting solutions is paramount.

Insights from other regions highlight the necessity of marrying industry best practices with domestic insights. But can regional adaptations keep pace with global players?

Innovations in technology, workforce training, and operational efficiency pave feasible paths to enhanced productivity, but sustaining momentum requires coordinated approaches.

Productivity gains promise not only economic benefits but substantial societal impacts. Recognizing and addressing this gap becomes integral in strengthening the next generation of manufacturers.

Clichés surround the manufacturing job market, often portraying it as gritty and uninspiring. In fact, modern roles offer progressive, challenging paths for diverse job seekers.

With myth-busting data demonstrating competitive wages and personal development, the narrative is shifting. Might this reshape public perception favorably?

Job stability, promotion prospects, and industry reinvention offer a modern glimpse into what the sector holds. How effectively can this resonate with younger demographics?

Positioning manufacturing careers as fulfilling, sustainable, and cutting-edge can spark a renaissance in public interest, pivotal for garnering available talent.

In unraveling the depths of the UK manufacturing landscape, one finds it teeming with possibilities, juggling traditional strengths and unprecedented innovation. For the informed professional, these insights outline a sector brimming with potential and fiercely competitive prospects. Share this enlightening journey with peers, bookmark these revelations, and stay attuned to further transformations as the UK manufacturing zeitgeist unfolds.